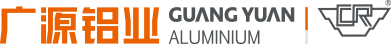

CNC Aluminium Products

-

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:cnc profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminium profiles are widely used in various industries due to their excellent properties such as lightweight, high strength, corrosion resistance, and flexibility. Deep processing of aluminium profiles involves various techniques to transform them...

-

Aluminum Extrusion Cnc Items

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:cnc profillesTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:100000 TONS ANNUALLYAluminum extrusion is a process that transform aluminum alloy into a wide range usage definitive cross-sectional profile.Aluminum is one third the density and stiffness of steel thus it was light strong and durable! People applied aluminum profiles... -

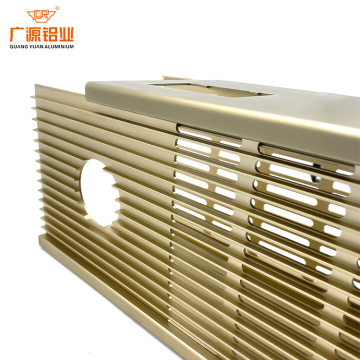

Cnc Machind Aluminum Products

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:cnc profilesTransportation:Land,Ocean,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS PER YEARThe advantage of aluminum profiles is light weighted, strong and durable, easily shaped, easy to assemble, recycled, cost effective, etc. Due to the advantage of aluminum profiles, it can be used in many industries and aspects! GUANGYUAN ALUMINUM as... -

Cnc Milled Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:cnc profilesTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYGuangyuan Aluminium Co., Ltd. was established in 1993 with more than 1,000 employees in our company. We are mainly specialized in the production of extruded aluminum CNC frame, CNC machined aluminum profiles, architectural aluminum profiles and... -

Customized Aluminum Extrusion CNC

Brand:GUANGYUANMin. Order:1Metric TonModel No:GYA0020Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 metric tons per monthPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearComapny Profile Guangdong Guangyuan Aluminium Co., Ltd. is one of the leading aluminium extrusion company in Foshan, China. We are mainly specialized in the development, production and marketing of aluminium extrusions and CNC aluminium profiles....