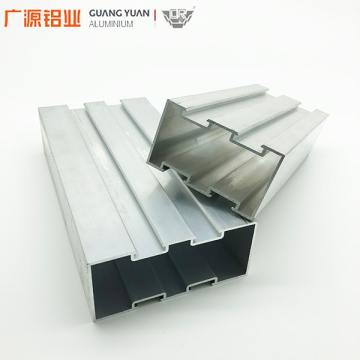

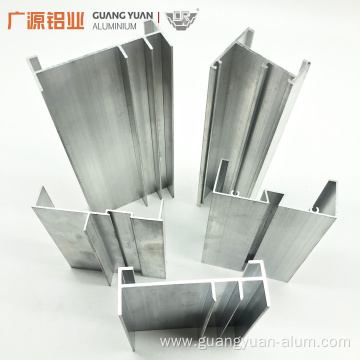

Architectural Aluminum Profiles

-

Brand:GUANGYUANMin. Order:1TonModel No:GY1022Transportation:Ocean,Land,AirPackaging:Inside: plastic film + Outside: Shrink film; or customized.Supply Ability:8000 tons/monthWhy need to do powder coated aluminium profiles 1. The higher the purity, the better the corrosion resistance. As we all know, pure aluminum reacts with oxygen in the air and produces a thin and dense natural oxide film on the surface of aluminum,...

-

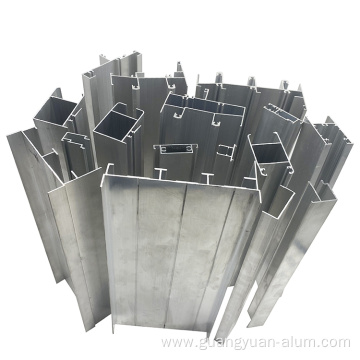

Aluminium Curtain Wall Section

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:curtainwall profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYGuangyuan as a leading aluminum profiles manufacturer with more than 28 years experiences in manufacturing high quality aluminium curtain wall section. We have full range of curtain wall aluminium profiles section, which can be categorized as:... -

Ghana Aluminum Profile Section

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:window door profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ OTHERSSupply Ability:8000 TONS FOR A MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum profiles is lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. They are available in various shapes and sizes to accommodate different window designs and sizes.... -

Lebanon Aluminum Profile Section

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:window and doorTransportation:Land,Ocean,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum and UPVC are two common materials which made for window and doors. Both UPVC and aluminum windows have their own advantages and disadvantages. The choice between the two depends on factors such as budget, desired aesthetics, energy... -

Mali Aluminum Profile Section

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:window and doorTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ OTHERSSupply Ability:8000 TONS FOR A MONTHPlace of Origin:FOSHAN, CHINAProductivity:100000 TONS ANNUALLYGuangdong Guangyuan Aluminium Co., Ltd. was founded in 1993, which is a professional aluminium doors and windows profile manufacturers in Foshan, China. We are committed to the development and production of aluminium door frame extrusions, aluminium... -

Window Shutter Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:louver profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAn aluminum profiles louver shutter slat is typically made of high-quality aluminium extrusion profiles. It is designed to be lightweight, durable, and resistant to corrosion, making it ideal for outdoor applications. The profile is usually extruded... -

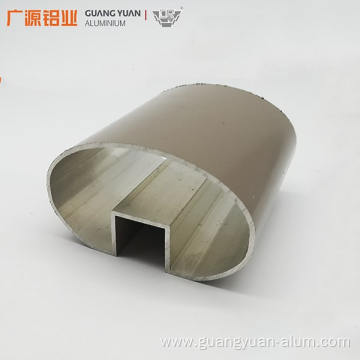

Oval Louver Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:louver profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYGuangyuan Aluminum has been engaged in the production and processing of aluminum profiles for more than 30 years which was equipped with 30 aluminum extrusion line of different specifications. We improve production efficiency without affecting... -

Extruded Railing Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:Handrail profileTransportation:Ocean,Air,Express,LandPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:100000 TONS ANNUALLYaluminum profiles is one of the most popular railing materials on the market today. It’s known by people for its lightweight strength and its ability to resist corrosion and rust. Railings are commonly used in the outside environment, thus, choosing... -

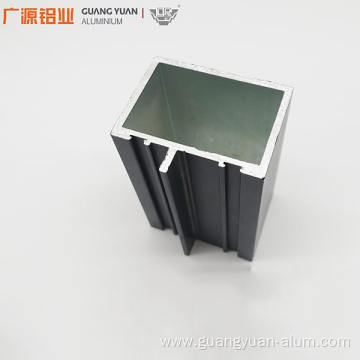

Office Partition Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:partition profilesTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ OTHERSSupply Ability:8000 TONS FOR A MONTHPlace of Origin:FOSHAN, CHINAProductivity:100000 TONS ANNUALLYAluminum profiles used to apply in different using areas because of it benefits. Especially aluminum profiles are widely used as Architectural Aluminum Profiles like window and door frame, curtain wall frame, room partition frame. An aluminum... -

aluminum extrusion sliding door

Brand:GUANGYUANMin. Order:1TonModel No:GYA0045Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 metric tons per monthPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearCOMPANY INTRODUCTION Foshan Guangyuan Aluminium Co., Ltd. was established in 1993, we are a leading professional aluminium profiles manufacturer in Foshan, China. We are mainly specialized in the manufacture of aluminium sliding door profiles,... -

Aluminum Profile for Windows

Brand:GUANGYUANMin. Order:1TonModel No:GYA0001Transportation:Ocean,Land,AirPackaging:protection film and hot shrink film, nylon wrapping, EPE foam and brown paperSupply Ability:5,000 tons per monthPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS ANNUALLYThe composition of aluminium windows and doors Aluminium profile for windows and doors is a kind of door and window frame decoration building materials made of aluminum profiles as raw material. Its advantages are good wind pressure resistance,... -

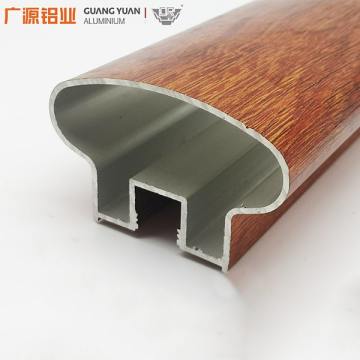

Wood Grain Aluminum Profile

Brand:GUANGYUANMin. Order:1TonModel No:GYA0050Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS MONTHLYPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARWOOD GRAIN ALUMINUM PROFILE The advantages of Wood Grain Aluminum Profile 1.Light and energy saving 2.Various colors for choice 3.Easy to fabricate and clean For wood grain aluminium profile, we usually first spray coat the primer coating on the... -

Powder Coating Aluminum Profile

Brand:GUANGYUANMin. Order:1TonModel No:GYA0051Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 metric tons per monthPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS ANNUALLYPOWDER COATING ALUMINUM PROFILES With the continuous development of powder coating technology, electrostatic powder coating on the surface of aluminum profiles is widely used by the current powder coating technology due to its unique advantages. The... -

aluminum door frame extrusions

Brand:GUANGYUANModel No:GYA0044Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearABOUT US Guangdong Guangyuan Aluminium Co., Ltd. was founded in 1993, which is a professional aluminium extrusion manufactuer in Foshan, China. We are committed to the development and production of aluminum door frame extrusions, aluminium door jamb... -

aluminum window frame extrusions

Brand:GUANGYUANMin. Order:1TonModel No:GYA0043Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 metric tons per monthPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearCOMPANY INTRODUCTION Guangdong Guangyuan Aluminium Co., Ltd. was established in 1993, and we are a leading aluminum profiles factory in Foshan, China. We are mainly specialized in the production of aluminum window frame extrusions, aluminium... -

Aluminum window frame extrusion profiles

Brand:GUANGYUAN ALUMINIUMMin. Order:1Metric TonModel No:GYA0003Transportation:Ocean,Land,Air,ExpressPackaging:protection film and hot shrink film, nylon tape, brown paper, EPE foam and cartonSupply Ability:5000 tons per monthPlace of Origin:Foshan, ChinaProductivity:60,000 tons per yearABOUT US Three trends in the development of aluminum window frame extrusion profiles Aluminium window extrusions include aluminum window frame extrusions and thermal break aluminum window frame extrusions. Among them, color aluminum and thermal... -

Aluminum window extrusion for Lebanon

Brand:GuangyuanMin. Order:1TonModel No:GYA0002Transportation:Ocean,Land,Air,ExpressPackaging:protection film and hot shrink film, nylon tape, poly bag, brown paper and cartonSupply Ability:5,000 tons per monthPlace of Origin:Foshan, ChinaProductivity:60,000 tons per yearPROPDUCT COMPANY INTRODUCTION Foshan Guangyuan Aluminium Co., Ltd. as an experienced aluminium extrusion supplier, which was established in 1993 with the headquarter located in Dali Town, Nanhai District, Foshan City, Guangdong Province. With the... -

Aluminum Window And Door Frame Profile

Brand:GUANGYUANMin. Order:1TonModel No:GYA0007Transportation:Ocean,Land,Air,ExpressPackaging:protection film and hot shrink film, nylon wrapping, EPE foam, brown paper, and cartonSupply Ability:5,000 tons monthlySelect Product Description Drawings Packing Methods Surface Treatmrnt Factory Tour The advantages of Aluminum Window And Door Frame Profile Guangyuan is a leading aluminum profiles manufacturer who has many years experiences focusing in... -

Glazed Aluminum Curtain Walls

Brand:GUANGYUANMin. Order:1TonModel No:GYA0040Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARSelect Product Description Packing Methods Surface Treatmrnt Factory Tour As a leading aluminum profiles manufacturer, Guangyuan has more than 28 years of experience in manufacturing high-quality aluminium extrusion profiles glazed aluminum curtain... -

Powder Coating Aluminum Curtain Wall System

Brand:GUANGYUANMin. Order:1TonModel No:GYA0039Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARSelect Product Description Packing Methods Surface Treatmrnt Factory Tour Guangyuan as a leading aluminum profiles curtain wall manufacturer enterprise, with more than 28 years experiences in manufacturing high quality Aluminium extrusion for... -

Aluminum Curtain Wall System

Brand:GUANGYUANMin. Order:1TonModel No:GYA0018Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARSelect Product Description Packing Methods Surface Treatmrnt Factory Tour Guangyuan as a leading aluminium extrusion profiles manufacturer enterprise, with more than 28 years experiences in manufacturing high quality aluminium profiles for curtain... -

Powder Coating Balcony Aluminum Railing

Brand:GUANGYUANMin. Order:1TonModel No:GYA0034Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARSelect Product Description Drawings Packing Methods Surface Treatmrnt Factory Tour Aluminum extrusion is one of the most popular railing materials on the market today. It is known for its light strength and ability to resist corrosion and rust.... -

High Quality Aluminum Balcony Balustrades

Brand:GUANGYUANMin. Order:1TonModel No:GYA0036Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER YEARSelect Product Description Packing Methods Packing Methods Surface Treatmrnt Factory Tour Aluminium extrusion is one of the most popular railing materials on the market today. It’s known by people for its lightweight strength and its ability to... -

Powder Coated Aluminum Tube Railing for Balcony

Brand:GUANGYUANMin. Order:1TonModel No:GYA0038Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS PER MONTHSelect Product Description Drawings Packing Methods Surface Treatmrnt Factory Tour Aluminum profiles are one of the most popular railing materials on the market today. It’s known by people for its lightweight strength and its ability to resist...