Industrial Aluminum Profiles

-

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:t slot profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYT-slot aluminum profiles are a type of extruded aluminum profile that features a T-shaped slot along its length. These profiles are commonly used in various industries, including manufacturing, construction, and robotics, for creating modular...

-

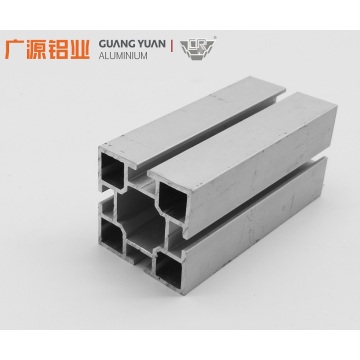

Customized Industrial Aluminum Profile

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:industrial profilesTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYIndustrial aluminum profiles are extruded aluminum shapes that are used in various industrial applications. These profiles are made from high-quality aluminum alloys and are designed to provide strength, durability, and versatility. It offers... -

Customization Industrial Aluminum Profiles

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:industrial profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYGuangdong Guangyuan Aluminium Co., Ltd. is a leading professional aluminium extrusion company in Foshan, China. Our company was established in 1993, with around 30 years in producing Extruded aluminium profile, extruded aluminum shapes, aluminum... -

Aluminum Profile for Roller Shutter Slats

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:roller shutterTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum profiles are extensively used in the construction industry for the fabrication of doors, windows, curtain walls, and structural components. They offer excellent strength-to-weight ratio, allowing for easy installation and energy-efficient... -

Custom Industrial Aluminum Profile

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:industrial profileTransportation:Ocean,Land,Express,AirPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum profiles can be used in a wide range of industries, including construction, automotive, aerospace, electronics, and more. They are commonly used for applications such as framing systems, conveyor systems, machine guarding, workstations, and... -

Enclosure Aluminum Profile Extrusion

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:indusrial profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLTAn aluminum extrusion enclosure is a type of protective casing made from extruded aluminum profiles. The extrusion process involves heating the aluminum and then forcing it through a die to create a specific shape. This type of enclosure is commonly... -

Heatsink Aluminum Profile Extrusion

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:heatsinkTransportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYThe heat sink profiles have a large surface area with fins or ridges that increase the contact area with the surrounding air, allowing for better heat transfer. Aluminium extrusion profiles is chosen for its excellent thermal conductivity and... -

Aluminum Profile for Heatsink Products

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:heatsink profileTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:Foshan ChinaProductivity:100000 TONS ANNUALLYHeat sink are extruded aluminum profiles that are designed to dissipate heat efficiently. They are commonly used in electronic devices such as computers, LED lights, and power amplifiers, where heat generation is high. Aluminum profiles is the most... -

Solar panel frame aluminum profile

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:solar profilePackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:100000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYSolar power generation is a technology that generates electrical power directly from sunlight. It offers a clean, renewable, and domestic energy source, and are essential components of a sustainable energy future. This kind of technology can be used... -

T Slot Aluminum Profile

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:t slotTransportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHGuangdong Guangyuan Aluminium Co., Ltd. is t slot aluminum extrusion manufacturers which was specialized manufacturing in aluminum T slot profile, T slot aluminium extrusion, 8020 aluminum extrusion and Aluminum modular profiles. We have around 30... -

6061 T6 Aluminum Heatsink Radiator for LED Lighting

Brand:GUANGYUANMin. Order:1TonModel No:heatsinkPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum extrusion is the most common material for aluminium alloy heat sink. Because of the nature of aluminum profiles, aluminium alloy heat sink has high thermal conductivity which allows heat to pass through it quickly in order to help the... -

6000 Series Large Aluminum LED Heatsink

Brand:GUANGYUANMin. Order:1TonModel No:GYA0029Transportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum led heatsink has the advantages of light weight, beautiful and durable, high heat dissipation rate, good shapeability, etc., and has been widely used in air conditioners, coolers and radiators. In my country, the use of aluminum profiles... -

custom aluminum heat sinks

Brand:GUANGYUANMin. Order:1TonModel No:heatsinkTransportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum extrusion is the most common material for heat sinks. Because of the nature of aluminum profiles, aluminium extrusion heat sink profiles has high thermal conductivity which allows heat to pass through it quickly in order to help the... -

Large Custom Extruded Aluminum Heatsinks

Brand:GUANGYUANMin. Order:1Piece/PiecesModel No:HEAT SINKTransportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS FOR A MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYChoosing aluminum profiles as heatsink material is the best choice! With the advantages of High thermal conductivity, Lightweight, Corrosion resistance, Good electrical conductivity, it has been widely used in various industries such as electronics,... -

6063 Extruded Aluminum Heatsink for LED Lighting

Brand:GUANGYUANMin. Order:1TonModel No:heatsinkTransportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS PER MONTHPlace of Origin:FOSHAN CHINAProductivity:100000 TONS ANNUALLYAluminum profiles are the most common material for heat sinks. Because of the nature of aluminium profiles, extruded aluminum heatsink have high thermal conductivity which allows heat to pass through it quickly in order to help the mechanical... -

aluminum heat sink extrusion

Brand:GUANGYUANMin. Order:1TonModel No:heatsinkTransportation:Ocean,Land,Air,Express,OthersPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:8000 TONS FOR A MONTHPlace of Origin:FOSHAN CHINAProductivity:150000 TONS ANNUALLYAluminum extrusion is the most common material for heat sinks. Because of the nature of aluminium extrusion profiles, aluminium extrusion for Heat Sink has high thermal conductivity which allows heat to pass through it quickly in order to help the... -

4040 4080 Anodized Modular Aluminum Profile

Brand:GUANGYUANMin. Order:1TonModel No:GYA0059Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearABOUT US Modular aluminum profile and modular aluminium extrusions used for a wide range of cabinet fabricate applications. All the modular aluminium profiles have inclined groove flanks engineered into the profile designs, which ensured modular... -

Anodized T slot Aluminum extrusion for 3D Printer

Brand:GUANGYUANMin. Order:1TonModel No:GYA0005Transportation:Ocean,Land,AirPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 tons monthlyPlace of Origin:Foshan, ChinaProductivity:60,000 tons yearlyGuangyuan Aluminium Co., Ltd. was established in 1993 with more than 1,000 employees in our company. We are mainly specialized in the production of anodized T slot aluminum extrusion for 3D printer, aluminium extrusion 2020, aluminum extrusion... -

Black Anodized Modular Aluminum Framing

Brand:GUANGYUANMin. Order:1TonModel No:GYA0060Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS MONTHLYPlace of Origin:Foshan, ChinaProductivity:6,000 metric tons per yearEstablished in 1993, Foshan Guangyuan Aluminium Co., Ltd has built a good reputation as one of Chinese leading manufacturers of aluminum extrusion. Our annual output has reached 60,000 tons.We specializes in manufacturing all kinds of aluminum... -

6000 Series Aluminum Structural Framing Profiles

Brand:GUANGYUANMin. Order:1TonModel No:GYA0061Transportation:Land,Express,Ocean,AirPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 METRIC TONS PER MONTHPlace of Origin:Foshan, ChinaProductivity:60,000 metric tons per yearPRODUCT DISCRIPTION -

Custom Large Aluminum Extrusions for Industry

Brand:GUANGYUANMin. Order:1TonModel No:GYA0008Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 tons monthlyPlace of Origin:ChinaProductivity:60,000 tons yearlyABOUT US Established in 1993, Foshan Guangyuan Aluminium Co., Ltd. have around 30 years’ experience in manufacturing aluminium profiles, large aluminum extrusions, extruded aluminium shapes, custom aluminum extrusions, aluminium channel extrusions... -

Aluminum U Channel Glass Railing

Brand:GUANGYUANMin. Order:1TonModel No:GYA0010Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 TONS PER MONTHPlace of Origin:FOSHAN, CHINAProductivity:60,000 TONS PER YEARABOUT US Guangdong Guangyuan Aluminium Co., Ltd. was established in 1993 as a large professional manufacturer of aluminum and glass railings, aluminum U channel glass railing, aluminium U channel sizes, aluminium U channel for glass, U shaped... -

Solar Panel Frames Aluminum

Brand:GUANGYUANMin. Order:1TonModel No:GYA0009Transportation:Ocean,Land,Air,ExpressPackaging:EPE foam, protection film and hot shrink film, nylon wrapping, poly bag, brown paper and carton, ect.Supply Ability:5,000 tons per monthPlace of Origin:FOSHAN, CHINAProductivity:60,000 METRIC TONS ANNUALLYALUMINIUM PROFILES FOR SOLAR PANELS Solar power generation is a technology that generates electrical power directly from sunlight. It offer offer a clean, renewable, and domestic energy source, and are essential components of a sustainable energy... -

6063 Aluminum Extrusions T-Slot for 3D Printer

Brand:GUANGYUANMin. Order:1TonModel No:GYA0019Transportation:Ocean,Land,Air,ExpressPackaging:POLY BAG/ PE FORM/ CRAFT PAPER/ WOODEN PALLET/ IRON TRAY/ OTHERSSupply Ability:5,000 TONS MONTHLYPlace of Origin:FOSHAN, CHINAProductivity:60,000 TONS ANNUALLYCOMPANY INTRODUCTION We use high-quality European-standard aluminum extrusions T-slot, 80 20 extruded aluminum, T slot structural framing and extruded aluminum T track with a smooth and corrosion-resistant appearance. Scientific structural...